As a professional manufacturer in a spiral duct forming machine, BYFO company always provide good quality and good after-sales, also ensure spiral pipe good sealing performance and perfect pipe appearance.

Description of Spiral Duct Forming Machine

The spiral air duct forming machine is professional for making straight round duct. It can greatly increase production efficiency. It’s automatic working by operating PLC control and manufacture different diameters and lengths according to the customer’s needs. The spiral air duct forming machine’s frame adopts full steel welding structure with enough hardness and rigidity. It also has been heated processed and highly frequently vibrated.

Spiral duct forming machine usually works with round pipe Elbow making machine, Seam welding machine, Angle iron round rolling machine and Three rollers bending machine and etc., to produce spiral round duct easily.

How to choose the suitable spiral duct machine

Our BYFO company not only provides customers with high-quality machines, but also provides high-quality after-sales and pre-sales services. According to the most essential needs and economic suitation of customers, we provide customers with practical solutions and recommend the most suitable machines.

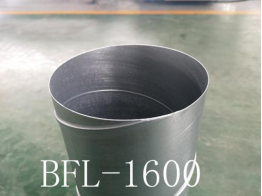

Next, I will discuss how to choose the right spiral machine by analyzing the differences between the BFL-1500 spiral duct machine and BFL-1600 spiral duct machine.

- The differencesbetween BFL-1500 spiral duct machine and BFL-1600 spiral duct machine

| Specification | BFL-1500

|

BFL-1600

|

|

picture |

|

|

| Mold

|

Steel strip mold

|

Fixed mold

|

| Diameter range

|

80-1500mm

|

100-1600mm

|

| Cutting Method

|

Sawing cutter

|

Roller cutter

|

| Working Speed

|

1-38m/min

|

50 m/min

|

- molds

- The 1500 is equipped with a steel stirp mold, which is cheap to manufacture, but easy to wear and requires high technical requirements for operators.

- The 1600 is equipped with a fixed mold, which is expensive, but durable,with good precision and easy to install.

So 10-15 pairs of molds are generally standard for 1500, and 5 pairs are standard for 1600. Additional molds will cost extra.

- the way of cutting

(1)1500 is a sawing cutting, the cut is slightly flawed,sparks and little loud noises when it is working.

(2)1600 is a flying slitter cutting with smooth cuts,when it is working,fast and gentle.

If the customer has higher requirements for the products made by the machine, and pursue a gentle cutting method,1600 is recommended.

- Machining diameter range

(1)The diameter of the round pipe processed by 1500 is 80-1500mm

(2)The diameter of the round pipe processed by 1600 is 100-1600mm

In fact, the size of the mold can be customized according to the customer’s requirements, but the standard mold will not exceed this standard.

- working speed

(1)The processing speed of 1500 is 1-45m/min

(2)The processing speed of 1600 is 1-80m/min

If the customer wants higher production efficiency, the 1600 should be the first choice.

- price

Obviously the 1600 parts and features are better than the 1500, so the 1600 is more expensive.

- Reference scheme

When the customer has sufficient funds for purchasing, has high requirements on the quality and productivity of the round tubes produced by the machine, expects a quieter working environment, and wants to avoid the follow-up purchase cost caused by mold loss, we recommend purchasing our BYL-1600 spiral duct machine.

When the customer has a limited procurement budget, does not have too many requirements for the working sound of the machine, pursues cost-effectiveness, and has certain experience in the installation of spiral molds, our BYL-1500 spiral duct machine is also a good purchase choice, because of the improvement and maturity of our production process, The quality and speed at which the 1500 produces round tubes is also fantastic.