JB23 TDC/TDF Corner Punching Auto Line

Products

News

-

How to Maintain a Elbow Duct Machine?

2024-04-08 -

How Does a Duct Seam Closer Work?

2024-03-28 -

Germany Customer Visited

2024-03-13 -

India Customer Visited

2024-03-06 -

20GP container ship to India

2024-03-06

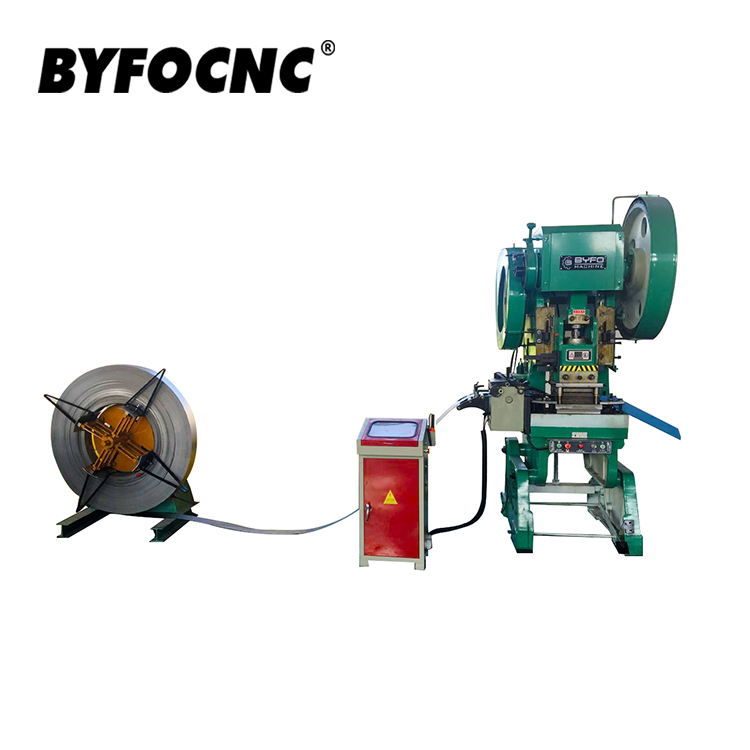

This is the duct tdf corner production machine with high efficient progressive moulds, with the constant increasing labor cost, this style corner equipment has been accepted by more and more clients. Also the high production efficiency is the most important for the present ducting business. This type TDC or TDF duct flange corner making machine is special suitable for the duct manufacturers with many years experience in this ducting industry. Just to change the TDC flange corners progressive moulds or TDF flange corners progressive moulds to obtain these two corners.

TDC/TDF Flange Corner Production Machine Technology drawing

TDC / TDF Flange Corner Production Machine components specifications

The whole TDC / TDF duct flange corner production machine is consisted of de-coiler, material feeding device, punching machine with Progressive Corner Moulds, etc

| De-coiler ( 800kg) | Leveler (Optional). | Punching Machine (C-Frame Fixed table press)

| Mechanical step feeder | TDC / TDF Progressive duct Corner moulds ( 1.0-1.2mm thickness TDF duct flange corner)

TDF Corner (we will customized for you,to do corners as you want)

TDC Corner

CNC feeder KRC series feeding machine

1 Uncoiler and straightener two in one style improve factory usable space.

- Straightening adopts the balance adjusting equipment and suitable for processing higher precision products.

- Roller adopts the solid bearing steel and hard chrome plating treatment.

Features:

- Equipped with precision adjusting micro components, Japan magnetic contractor and electronic components, minimum breakdown and long operating life.

- Integrated with straightener and uncoiler into one machine, save volume, suitable for board processing. Automatically adjust feeding time according to output speed.

- Hard-chrome plated rollers adopts the solid bearing steel, low wear and high precision

- Controlled by modern transducer, a various speed control is used for normal and high speed operation, keep pace with straightening, stable feeding.

- Integrated with Uncoiler and straightener. Save volume, suitable for board processing. Automatically adjust feeding time according to output speed.

- All rolls are made of bearing steel, have all been quenched, hard-chrome plated and grinded with mim HRC60 degree.

- Use Japanese electromagnetic contact and electric parts, long service life .

- A step-less variable speed control is used normal and high speed operation, control by modern frequency converters, keep pace with straightening, stable feeding.

- Leveler inclines appropriately to reduce feeding loop distance.

- Constructed with highly rigid structure and designed with a powerful motorized feeder

JB23 Models mechanical press machine

1.Main Features:

JB23 punch press is a suitable open type crank press featuring a left and right open type machine body (i.e. C-shaped machine body). Its steel plate welded body has high shock-absorbing performance. Its novel overall design gives the machine elegant appearance.

2.Specifications:

| Parameter | Unit | JB23-63 | JB23-80 | |

| Nominal Capacity | KN | 630 | 800 | |

| Nominal Stroke | mm | 6 | 7 | |

| Slide Stroke | mm | 110 | 120 | |

| Slide Stroke Per Minute | T/M | 50 | 38 | |

| Maximum Die Set Height | mm | 360 | 440 | |

| Die Height Adjustment | mm | 80 | 90 | |

| Throat Depth | mm | 260 | 350 | |

| Distance Between Uprights | mm | 350 | 450 | |

| Slide Bottom Size | L x R | mm | 300 | 430 |

| F x B | mm | 260 | 360 | |

| Stem hole Size | Dia | mm | 50 | 60 |

| Depth | mm | 70 | 75 | |

| Bolster Size | L x R | mm | 760 | 950 |

| F x B | mm | 480 | 650 | |

| Diameter of Blanking Hole | mm | 180 | 200 | |

| Bolster Thickness | mm | 80 | 100 | |

| Max. Angle of Inclination | 。 | 20 | 20 | |

| Bolster Surface Height | mm | 810 | 850 | |

| Overall Size | F x B | mm | 1810 | 2060 |

| L x R | mm | 1350 | 1715 | |

| H | mm | 2740 | 3290 | |

| Distance between foundation bolts | F x B | mm | 1180 | 1360 |

| L x R | mm | 850 | 1010 | |

| Motor Power | Kw | 5.5 | 7.5 | |

| Weight | Kg | 3800 | 5600 | |

3.Main Configuration:

4.The Machine of Whole structure and Characteristics:

J23 Series Presses is one of the new generation of plate process and developed by Byfo company,The press is for cutting, punching, blanking, bending and light stretching work

- C- frame provides maximum rigidity and minimum deflection for accurate parts and long tool life.Steel-welded frame, high rigidity and less deformation Compact.Thick plates and large columns provide you with the stable platform you need for your demanding application.

- Wide body frame eliminating vibration for improved ide life and machine,which means economical and practical. Operation space is wide, and the movable bolster could be moved out of frame to set the die. The structure is simple beautiful.

- High accuracy, high efficiency, simple and convenient operation, good performance, favorable price and best service.

5.Transmission control and brake systems:

- Use the combine of dry friction clutch and brake pneumatic,rigid interlocking,reliable piece of friction material semi-metallic friction material SMFM-88,less pollution, long life. With the transfer torque, rotational inertia is small, smooth transmission, flexible operation, convenient of installation and maintenance

- Die height adjustment of slider with manual mode, the scale display. Extended by four triangular rail, easy adjustment.

3.Use double safety valve to ensure the accurate implementation of the clutch instruction.

- Electrical control is installed PLC, 8 group cam controller, reliable action.

- Electrical control adopts Omron PLC for centralized control, improved machine reliability

- Proximity switch with 8 groups consisting of Schneider cam controller, reliable synchronization detection and monitoring.

- Machine is with both hands button and foot switch to achieve continuous,single and inchingpractices.

- Can move the ram up slowly,which allows the operator to control Mold adjustment conveniently.

6.Worktable and the controller: