Dcp-1000 Electric Elbow Making Machine

Products

News

-

How to Maintain a Elbow Duct Machine?

2024-04-08 -

How Does a Duct Seam Closer Work?

2024-03-28 -

Germany Customer Visited

2024-03-13 -

India Customer Visited

2024-03-06 -

20GP container ship to India

2024-03-06

Dcp-1000 Electric Elbow Making Machine

BYFO elbow making machine is an indispensable equipment in the mechanical production of round ventilation pipes. It is professionally used for the connection of round pipes, especially in the production of elbows. It is suitable for the production and use of ventilation and refrigeration and environmental protection engineering pipeline interfaces.

BYFO elbow making machine is an indispensable equipment in the mechanical production of round ventilation pipes. It is professionally used for the connection of round pipes, especially in the production of elbows. It is suitable for the production and use of ventilation and refrigeration and environmental protection engineering pipeline interfaces.

Structure

–Frame

The angle steel and the steel plate are welded and assembled, the overall rigidity is good, and the surface of the worktable is chrome-plated.

–Transmission mechanism

Two sets of completely independent transmission mechanisms, each group consists of two rollers, a first-level V-belt, a first-level worm gear, and a first-level gear drive.

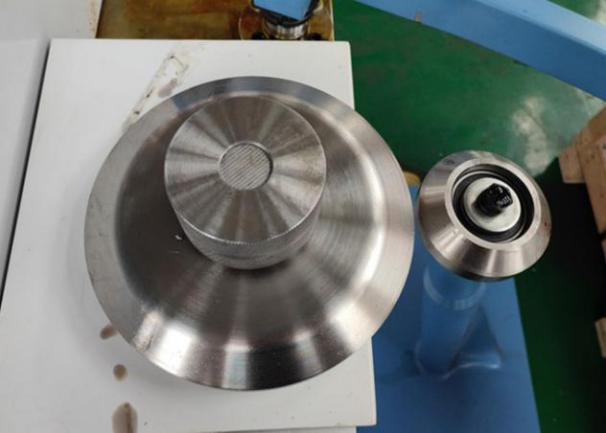

–Forming roll (2 sets)

The elbow making machine has 2 sets of forming rolls, Using GR15 bearing steel, has good wear resistance, high and uniform hardness.

The diameter of the big wheel is 185mm, and the diameter of the small wheel is 95mm.

–Foot switch

Control two groups of forming wheelsseparatly, foot switch is movable and can stop the machine any time by theemergency button.

–Adjustable handwheel

Adjust the height of the machine table for worker operation

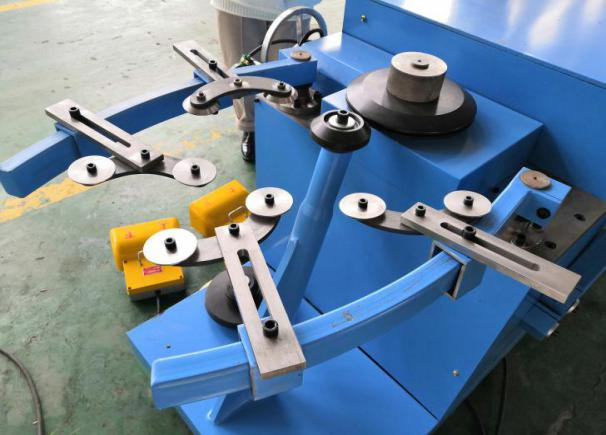

–Arms folded & Brackets(3sets)

The elbow making machine has two arms foled, brackets for both sides, bracket with 3 sets, this using A3 iron,

the wheels on the carrier are 50mm in diameter, arm and bracket fixed with screws,

used to hold round tubes to facilitate the

forming of the forming wheel.

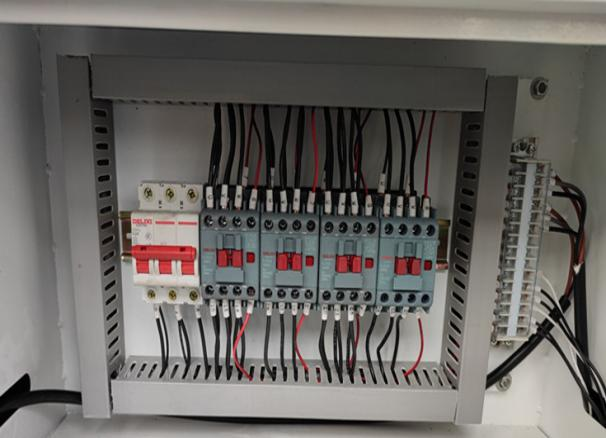

–Distribution box

Use a Chinese contactor

use and operation

–Mainly Specification

According to the different processing capacity and scope, the round pipe elbow making machine produced by our company can be divided into DCP-700, DCP-1000, DCP-1250 and other models.

Type | DCP-1000 |

Max. thickness | 0.4-1.2mm |

Dia. range | 100-1000mm |

Forming speed | 7r/min |

Motor power | 1.5kwx2 |

Weight | 556kg |

Dimension | 2100x820x890mm |

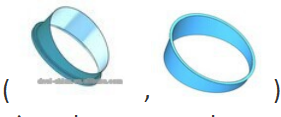

–elbow duct pictures

performance characteristics

Electric elbow machine has the advantages of reasonable structure, stable performance, practical and convenient. The bone shape produced by the electric elbow machine has good straightness, and the size and angle are accurate. After occlusion, the air duct has high sealing performance and is firm and durable.

- Dualworking

- flexibility – eliminates equipment’s changing over and reduces tool’s changing.

- Higherproduction

- Flangingspeed Up to 4m per

- Higher

- Materialthickness: up to 5mm Galvanized steel &1.0mm stainless steel.

- Improvedseam’s

- Optimizedroller’s

- Virtuallyno

- Nolubrication & all rotating parts made of hardened, high grade

- Manufactureof segment bends, reducers, end covers and offsets & attachment of cams forMETU

- 2separate workstations achieve high flexibility: a flanging station and a closing machine is always ready for operation without time-consuming conversion.

How to operate

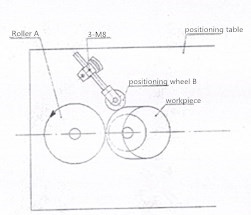

- Turn it on when it is turned on, observe whether the rotation direction of the roller is correct, and make sure that the roller rotates in the marked direction. (Rotate A counterclockwise)

- When forming, place the workpiece on the positioning table, and adjust the 3-M8 screws on the positioning table to make the positioning wheel stick to the workpiece (as shown in the figure), so as to control the swing range of the workpiece during rotation.

- Gently press the top of the workpiece feeding side with your hand, so that the bottom edge of the workpiece feeding side is against the positioning table, then start the machine and shake the handwheel to slowly press the roller A to the roller B until it is formed.

- Electric elbow maker is the special equipment for both connecting lock and seaming when processing on metal plate round pipe and round elbow. By adjusting the position of pointer on the hand wheel, two locks

will be formed separately at the mouth of the round

pipe, the connect the month of the pipe for two locks on the other set of the

roller to form an elbow