U Shape Auto Duct Line 5

Products

News

-

How to Maintain a Elbow Duct Machine?

2024-04-08 -

How Does a Duct Seam Closer Work?

2024-03-28 -

Germany Customer Visited

2024-03-13 -

India Customer Visited

2024-03-06 -

20GP container ship to India

2024-03-06

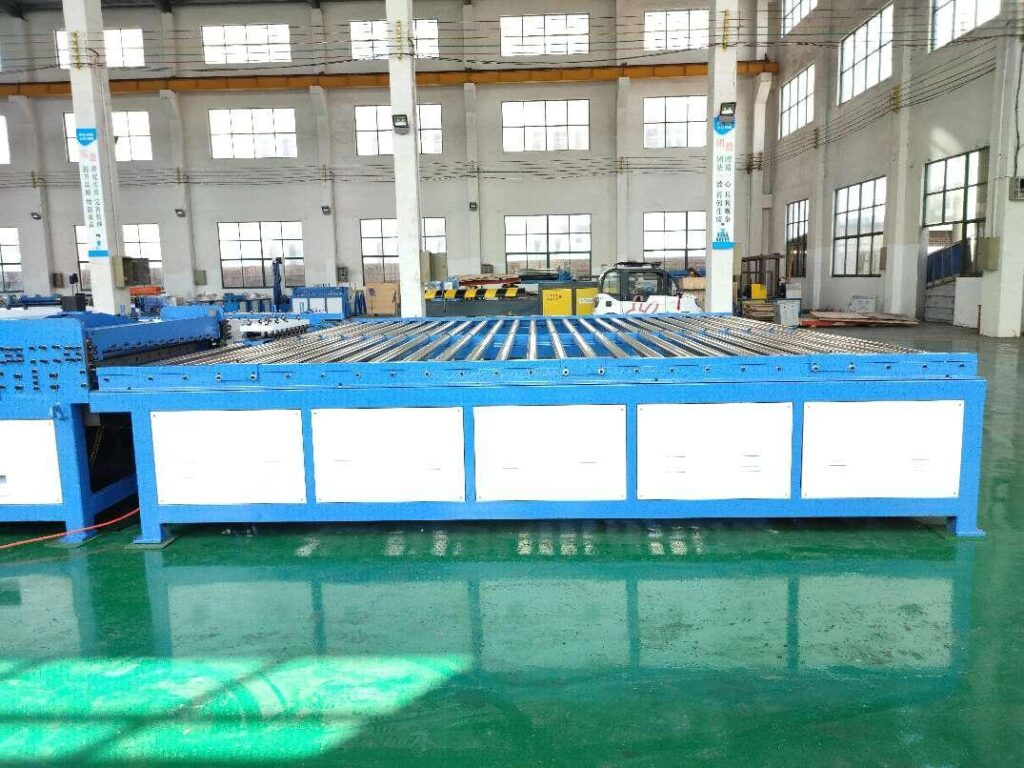

U Shape Auto Duct Line 5

Nanjing BYFO Machinery Co., Ltd. is a professional manufacturer of air duct making machine. U shape auto duct line 5 is a large-scale production machine in the ventilation industry, which is generally suitable for the production of square air ducts. Because of its U-shaped structure, small footprint and simple assembly, it is favored by many manufacturers in the ventilation industry at home and abroad. It’s mainly used for TDF/angle iron/C-shaped flange making, the daily capability is 1500-2000 square meters. Only input duct sizes into controller, then the production line can automatically complete uncoiling, leveling, beading, punching, shearing, duplex locking, forming TDF/angle steel/C-shaped flange and folding.

Main technical parameters

The standard U-shaped duct production line 5 has 4 models. The biggest difference between each model is the processing plate thickness and processing plate width. The maximum processing plate thickness of the standard model is 1.5mm, and the maximum processing plate width is 1500mm. If you want to process thicker and larger sheets, the machine can be customized according to customer needs.

| Model | Sheet thickness (mm) | Max width (mm) | Max working speed (m/min) | Dimensions (mm) | Power (KW) | Weight (T) | ||

| L | W | H | ||||||

| BYL-U-V-1.2*1250 | 0.5-1.2 | 1250 | 15 | 14000 | 5000 | 1500 | 30 | 13 |

| BYL-U-V-1.5*1250 | 0.5-1.5 | 1250 | 15 | 14000 | 5000 | 1500 | 33 | 13 |

| BYL-U-V-1.2*1500 | 0.5-1.2 | 1500 | 15 | 14000 | 5400 | 1500 | 30 | 14 |

| BYL-U-V-1.5*1500 | 0.5-1.5 | 1500 | 15 | 14000 | 5400 | 1500 | 33 | 14 |

Performance features

- U-shaped structure, small footprint, simple assembly, suitable for small and medium workshops.

- Driving feeding mechanism with pneumatic servo manipulator helps to ensure stability and speed of the machine, and the accuracy of its locating system.

- It only takes 20-25 seconds to make one L-shaped work piece and the efficiency will double comparing with the linear type.

- Without moving back and forth the fixed locking machine is able to improve the efficiency.

- All the rolling reels are made of bearing steel so that the lifetime prolongs by more than 5 times.

- Under the material-saving mode of CNC system, waste is less than 20mm per roll.

- With production memory functions, the production orders can be tracked and checked.

Basic configuration

- One coil rack: included4 support unloading racks and one integral bracket, and 4 motors.

Galvanized coils can be installed in adjustable synchronous inner support and unloading rack, the maximum load is 8 tons, the inner diameter of the coil isφ480-610 mm, and the outer diameter of the coil is φ1100 mm (maximum).

The size of the integral bracket is 5600mm*2000mm*1500mm. Each motor power is 1.5KW.

Integral bracket

support unloading rack

1.5kw Motor

2.One host

Host,it adopts integral profile welding, includes feeding, leveling, beading, punching, shearing and CNC control system.

The feeding part,adopts photoelectric induction control and system control, and the coil material can automatically advance and retreat.The baffle is made of galvanized material, which can reduce wear and prevent rust, and last longer.

Leveling and beading part equipped with 9 rollers,the material of the roller is 45# steel, the diameter of the roller is φ80mm×1350mm. Beading type standard “U” shape, bead slope interval 230mm

The feeding part,adopts photoelectric induction control and system control, and the coil material can automatically advance and retreat.The baffle is made of galvanized material, which can reduce wear and prevent rust, and last longer.

The shearing part mainly use hydraulic control, the cutting tool material is 9 CrSi, the shearing plate thickness range is 0.5-1.2 mm

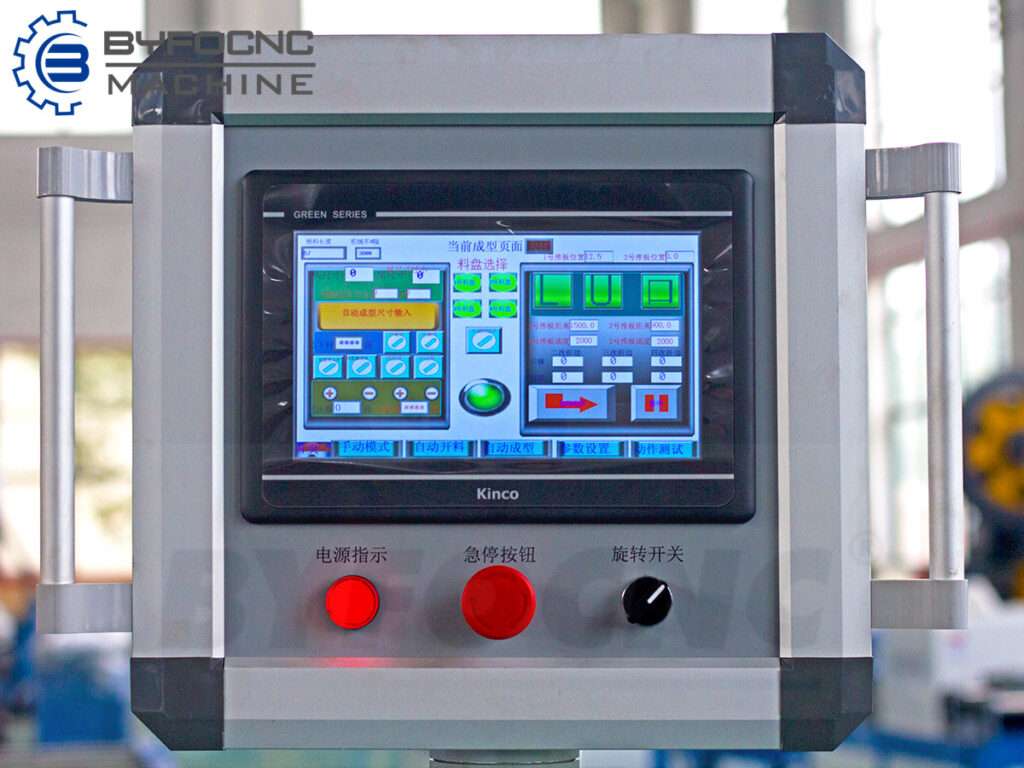

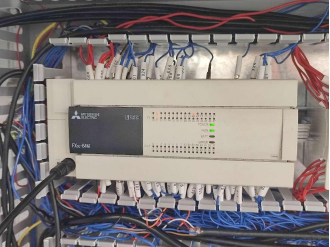

CNC control system,adopts color high-resolution touch screen of Japan’s Mitsubishi. The system interface is equipped with 10 order management , which can realize free conversion between continuous or single orders, greatly improving production efficiency aluminium alloy suspension arm makes the machine easy to operate.

The hydraulic system of this host part adopts Shenchi SNC hydraulic components, the hydraulic pressure is 8-12MPa, and the oil pump motor is 4KW and an air-cooled box for cooling

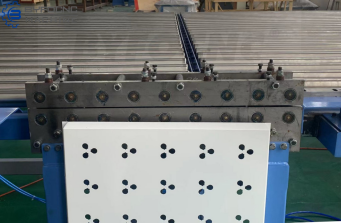

Optional: Flange hole punch mold

Optional: Centre hole punch mold

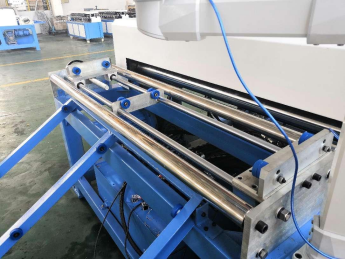

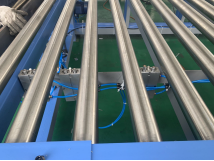

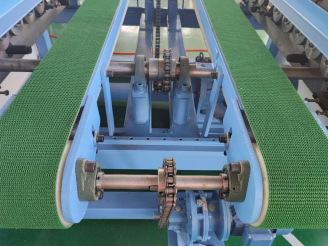

3.Two stainless steel roller conveyer platforms

The size of each conveying platform is 5600mm*2000mm, equipped with 49 stainless steel rollers, and two 1.5kw fixed motors drive the stainless steel rollers to run.3 sets of air valves push 7 cylinders to run on linear guides to push the sheet from No. 1 conveying table to No. 2 conveying table.And the transfer table is equipped with photoelectric induction, which can sense the position of the plate, so as to better push the plate.

Stainless Steel Roller

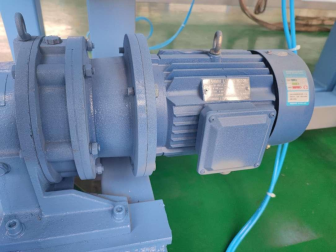

1.5KW motor power

Photoelectric induction

air valves

Cylinder

Linear Guides

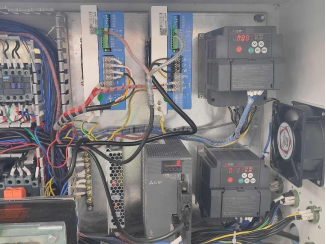

The electrical cabinet of this auto duct line is mounted on the side of the transfer platform 2. Equipped with aviation plug with high safety factor, connecting flange machine and folding machine on the back

electrical cabinet

aviation plug

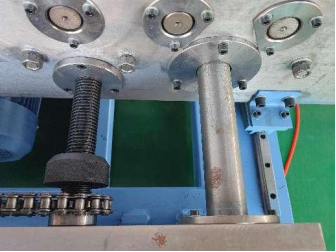

4.One fixed joint Pittsburgh lock machine

The Pittsburgh lock machine has 9 sets of roll wheels, the material of the roll wheels is GCr15, the roll former shape is Pittsburgh lock, which can perfectly match the right-angle edge folded by the back folding machine. This part use 3KW motor .

Back of the Pittsburgh lock machine

Front of Pittsburgh lock machine

3kw motor

Roll wheels

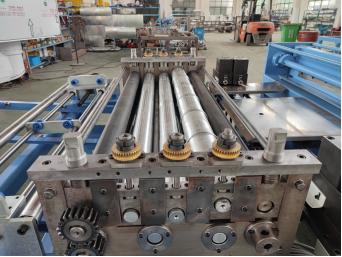

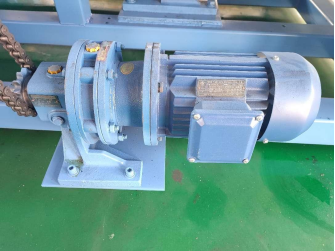

5.One duplex TDF flange forming machine ( Optional:One duplex angel iron flange forming machine )

Duplex TDF flange forming machine can make TDF flange at two sides of duct simultaneously. The outer width of the TDF flange is 35mm and the inner width is 32mm. It’s double-sided driven and able to meet mobile requirements of high load and high accuracy with linear guides of Taiwan Hiwin. Each side of the flange machine is equipped with 16 sets of GCr15 wheels, which are high-strength, not easy to wear, and have a service life that is more than 5 times higher than that of ordinary Cr15. The length of the conveyor belt is 5300mm, which can convey the board stably and accurately. There are adjustment wheels on both sides of the flange machine, with lead screw and drive shaft, it can adjust the distance before the forming wheels on both sides, and the shrinkage range is 800-1500mm. This part uses two motors, one is 1.5KW and the other is 5.5KW.

The forming wheel made of GCr15 material is more durable and wears less.

The belt conveyor conveys the sheet, which is safe and stable, and reduces the damage to the sheet.

adjustment wheels

Lead screw and drive shaft

5.5kw motor drives the forming wheels on both sides of the machine to running .

1.5kw motor drives the chain and then drives the conveyor belt to move.

Optional: Duplex angel iron flange forming machine can be selected according to customer needs. It can from 7 mm width angel iron flange at two sides of duct simultaneously. It’s double-sided driven and able to meet mobile requirements of high load and high accuracy with linear guider of Taiwan Hiwin. Each side of the flange machine is equipped with 9 sets of GCr15 wheels, which are high-strength, not easy to wear, and have a service life that is more than 5 times higher than that of ordinary Cr15. The length of the conveyor belt is 2730mm, which can convey the board stably and accurately. There are adjustment wheels on both sides of the flange machine, with lead screw and drive shaft, it can adjust the distance before the forming wheels on both sides, and the shrinkage range is 800-1500mm. This part uses two motors, one is 1.5KW and the other is 3KW.

The belt conveyor conveys the sheet, which is safe and stable, and reduces the damage to the sheet.

Manual remote control wheel to adjust the distance between the forming wheels on both sides.

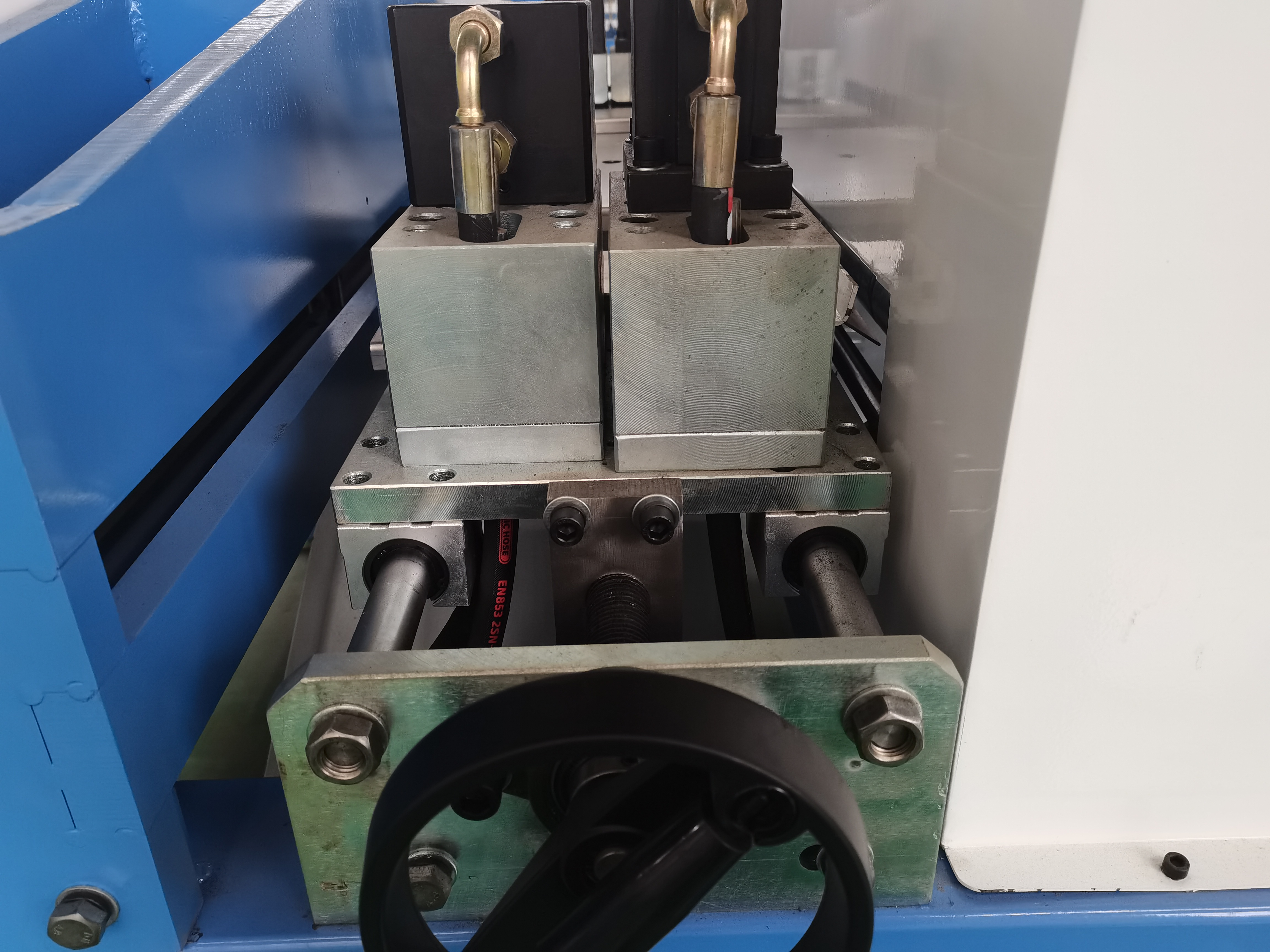

6.Transfer bending platform

The servo feeding platform transmits the sheet, the ball screw and the guide rail push the manipulator to grasp the material to position and feed the material, the system automatically calculates the bending size, and the hydraulic bending machine folds the square at one time.

Two pressure rollers ensure the smooth advancement of the sheet on the conveyor belt.

The manipulator grabs the board for feeding, and the photoelectric sensor induction confirms the position of the board.

Ball Screws and Guides.

Emergency stop switch and other buttons are more convenient for customers to operate the equipment.

The bending die material is 9CrSi, which is very durable.

The bending part is equipped with oil cylinder and hydraulic system, which has high precision and high speed.

- Main import configuration

| Name | Brand | Model | unit | quantity |

1 | PLC controller | Mitsubishi Japan | FX3GA-60MT-CM | PCS | 1 |

2 | SCREEN | Mitsubishi Japan | GS2110 | PCS | 1 |

3 | Inverter | Mitsubishi Japan | RF-E740-1.5K-CHI | SET | 1 |

4 | Inverter | Mitsubishi Japan | RF-E740-3.7K-CHI | SET | 1 |

5 | Inverter | Mitsubishi Japan | RF-E740 | PCS | 1 |

6 | Encoder | NEMICON | OVW2-12-2MHC | PCS | 1 |

7 | Relays | IDEC | RJ2S-CL-D24-SJ2S-05B | sets | 36 |

8 | Servo motor | Mitsubishi Japan | HF-SN102J-S100 | PCS | 1 |

9 | Pump motor | Siemens | 4 kw | SET | 1 |

10 | Pump | Beijing Huade |

| SET | 1 |

11 | Servo AMP | Mitsubishi Japan | MR-JE-100A | PCS | 1 |

12 | Hydraulic valve | KUOTEN | Dsg-02-3C2-NL-D2-ST | SET | 1 |

13 | converter motor | Nanjing Fangli | WPDS100-50-YVF1.5KW | SET | 2 |

14 | converter motor | Nanjing Fangli | RV110-40-YVF3KW | SET | 1 |

15 | High temperature tube | Taiwan | 50-60MPa | SET | 1 |

16 | Contactor | Schneider | 1810 / 1210 | SET | 8 |

Mitsubishi Japan PLC

Mitsubishi Japan inverters

Mitsubishi Japan screen

Taiwan Hiwin linear guide

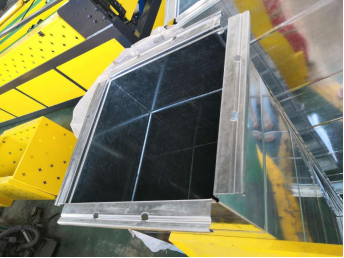

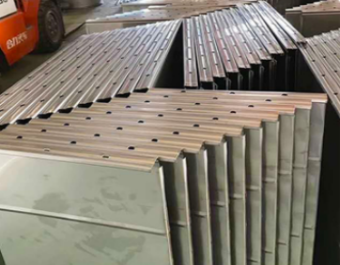

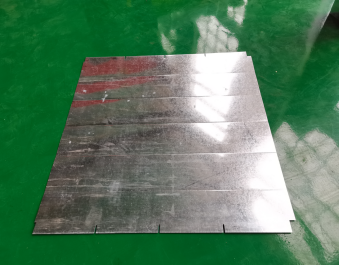

- Final shaped products

Standard product :TDF Flange square duct with pittsburgh lock and single lock.

Optional products: TDF Flange square duct with pittsburgh lock and single lock and flange hole and center hole.

L-piece ducts

Flat beading and punching and shearing