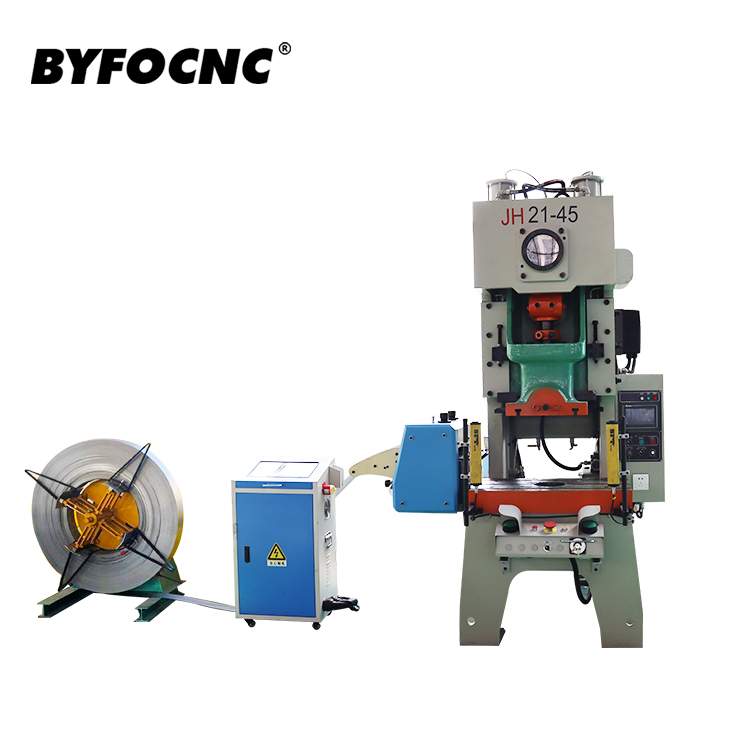

JH21 Models Punching Auto Line

Products

News

-

How to Maintain a Elbow Duct Machine?

2024-04-08 -

How Does a Duct Seam Closer Work?

2024-03-28 -

Germany Customer Visited

2024-03-13 -

India Customer Visited

2024-03-06 -

20GP container ship to India

2024-03-06

This is the duct tdf corner production machine with high efficient progressive moulds, with the constant increasing labor cost, this style corner equipment has been accepted by more and more clients. Also the high production efficiency is the most important for the present ducting business. This type TDC or TDF duct flange corner making machine is special suitable for the duct manufacturers with many years experience in this ducting industry. Just to change the TDC flange corners progressive moulds or TDF flange corners progressive moulds to obtain these two corners. It can also replace the mold for the production of G Clip or other products.

|

|

|

| TDC corner | TDF Corner | G clip |

TDC/TDF Flange Corner Production Machine Technology drawing

CNC feeder

- Uncoiler and straightener two in one style improve factory usable space.

- Straightening adopts the balance adjusting equipment and suitable for processing higher precision products.

- Roller adopts the solid bearing steel and hard chrome plating treatment.

- Equipped with precision adjusting micro components, Japan magnetic contractor and electronic components, minimum breakdown and long operating life.

- Integrated with straightener and uncoiler into one machine, save volume, suitable for board processing. Automatically adjust feeding time according to output speed.

- Hard-chrome plated rollers adopts the solid bearing steel, low wear and high precision

- Controlled by modern transducer, a various speed control is used for normal and high speed operation, keep pace with straightening, stable feeding.

- Integrated with Uncoiler and straightener. Save volume, suitable for board processing. Automatically adjust feeding time according to output speed.

- All rolls are made of bearing steel, have all been quenched, hard-chrome plated and grinded with mim HRC60 degree.

- Use Japanese electromagnetic contact and electric parts, long service life .

- A step-less variable speed control is used normal and high speed operation, control by modern frequency converters, keep pace with straightening, stable feeding.

- Leveler inclines appropriately to reduce feeding loop distance.

- Constructed with highly rigid structure and designed with a powerful motorized feeder.

JH21 Models mechanical press machine

| Parameter | Unit | JH21-45 | JH21-63 | JH21-80 | |

| Nominal force | KN | 450 | 630 | 800 | |

| Nominal force travel | mm | 4 | 4 | 5 | |

| Slider travel | mm | 100 | 120 | 140 | |

| The number of trips | Fixed | Min-1 | 80 | 70 | 60 |

| variable | 70-90 | 60-80 | 50-70 | ||

| The maximum mold height | mm | 270 | 300 | 320 | |

| Modular height adjustment | mm | 60 | 80 | 80 | |

| Slider center to body distance | mm | 230 | 300 | 300 | |

| Work Table size (w*l) | mm | 440*810 | 580*900 | 580*1000 | |

| Work table Billet size (Upper hole diameter * Depth * Lower hole diameter) | mm | Φ180*30*Φ160 | Φ200*40*Φ160 | Φ200*40*Φ160 | |

| Work table thickness | mm | 110 | 110 | 120 | |

| Body table hole size | mm | 300*300 | 390*460 | 390*520 | |

| Slider bottom size | mm | 340*410 | 400*480 | 420*560 | |

| Mold handle hole size ( Diameter * Depth) | mm | Φ40*60 | Φ50*80 | Φ50*80 | |

| The distance between the columns | mm | 550 | 560 | 640 | |

| Main power | KW | 5.5 | 5.5 | 7.5 | |

| Dimensions (L*W*H) | mm | 1390*1200*2400 | 1580*1205*2580 | 1640*1290*2800 | |

| Weight | kg | 3450 | 5200 | 6720 | |