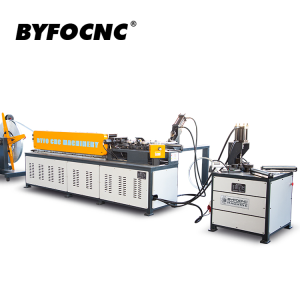

1600 Spiral Air Duct Machine

Products

News

-

How to Maintain a Elbow Duct Machine?

2024-04-08 -

How Does a Duct Seam Closer Work?

2024-03-28 -

Germany Customer Visited

2024-03-13 -

India Customer Visited

2024-03-06 -

20GP container ship to India

2024-03-06

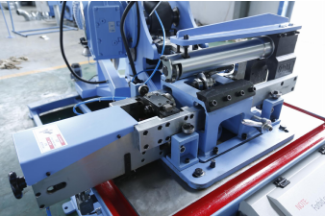

1600 Spiral Air Duct Machine

Byfo 1600 spiral duct machine is mainly used for building construction round pipe. It has the advantages of small air supply resistance, high strength and good sealing performance, fast processing and conversion of various diameters, high production efficiency, stable performance and wide length range. Suitable for applications in filtration, ventilation, dust removal, environmental protection, construction and other industries.

Introduction of Main Configuration

–Composition

This equipment consists of three parts: decoiler, main machine and discharge table.

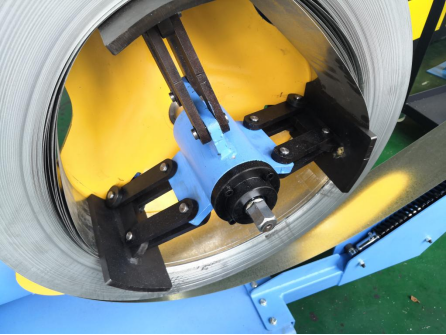

- Decoiler

The decoiler is integrated with the main machine and is equipped with a pneumatic brake device and a material belt buffer device. The diameter of the inner roll is 460-520mm, the maximum diameter of the outer roll is 1200mm, and the maximum load is 1100kg. The decoiler is installed on the slide rail and is driven by a small motor at the tail to adjust the feeding angle.

- Main machine

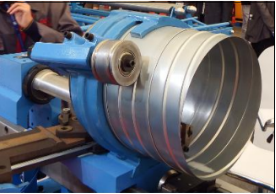

- Forming roller: roll the steel strip in multiple passes; the feed roller can be adjusted left and right to adjust the size of the left and right flanging of the steel strip.

- Feeding roller: plays the role of feeding, there is an oil cylinder below to tighten the material belt, and the pressure is adjusted by an electric contact pressure gauge.

- Discharge plate: plays a guiding role, and is equipped with a folding wheel to fold the sub-mother mouth of the material belt.

- Coil part: forming head mold, closing wheel, etc. The closing wheel can be raised and lowered, and can also be fine-tuned left and right.

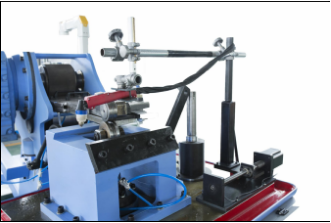

- Cutting part: rolling shear or plasma synchronous tracking cutting, stepper motor drives ball screw drive, precise control.

- Control part: electrical system, hydraulic system, pneumatic system.

- PLC Console

- Discharge table

Outlet rack: 2.1 x 1.0 x 1.0 m. The height of this air duct bracket is adjustable, and the pneumatic turning function is suitable for air ducts below 800mm. One bracket can accept pipes 2-4 meters long, and multiple brackets can be selected.

–Technical parameters

| Diameter range | 100-1800mm |

| Thickness range | Galvanized sheet: 0.5-1.2mm, width 137mm |

| Stainless steel: 0.45-0.8mm, width 137mm | |

| Decoiler | inner coil diameter 460-520mm |

| outer coil maximum diameter 1200mm, maximum load 1100kg | |

| Bite seam | Outer bite

|

| Production speed | 0-35 m/min, adjustable |

| Cutting method | Rolling shear cutting |

| Plasma cutting | |

| Fixed length cutting | Infrared sensor switch |

| Computer fixed length | |

| Power system | Pneumatic for shearing and turning |

| Hydraulic for feeding roller clamping | |

| Forming head mold | Steel |

| Total weight of equipment | 2000kg |

| Overall dimensions of the equipment | Main unit: 3.4 x 1.7 x 1.7 m |

| Outlet rack: 2.1 x 1.0 x 1.0 m | |

| Total equipment power | 16KW |

| Console | Touchscreen/button |

| Power supply | Can be customized |

–Basic Accessories

- Fixed mold: The material of the fixed mold is A3 iron steel, We will provide 5 pcs fixed molds, all sizes will follow your request, size range: 100-1600mm .

- Optional accessories: stiffener. There are two styles of single wave and double wave, which can be installed on the mold. Generally, 250-1000 diameter pipes can be reinforced to increase the strength.

–Two cutting methods

The spiral duct machine adopts a power system combining pneumatic and hydraulic, which is controlled by PLC and is easy to operate. There are two cutting methods: roll shear cutting and plasma cutting.

The advantage of roll shear cutting is that the incision is smooth and the cutting is pollution-free. The disadvantage is that the cutting angle needs to be readjusted when changing the mold, and the blade gap is adjusted according to the thickness of the plate.

Another option: The advantage of plasma cutting is that it is suitable for any pipe diameter and thickness, but the disadvantage is that there is a lot of smoke and dust when cutting

–Spiral duct machine configuration list

| Configuration 1 | Configuration 2 | |

| Motor reducer | Guomao or Zhongyan | |

| Inverter | SAICER | ABB |

| PLC | Xinjie | Siemens |

| Electrical components | Chint | Schneider |

| Touch screen | WeiKong | Siemens |

| Hydraulic valve | Ward | |

| Pneumatic Components | Made in China | |

| Linear Guides | TBI | |

| Plasma Power | Jasic |