Picture this, a symphony of steel and precision that creates the robust backbone of our infrastructures – spiral ductwork. These winding ribbons of metal might seem like a mundane afterthought, just a routine component hidden behind the paneling of buildings, but their creation is an intricate dance between man and machine. This is where the magic starts, with a spiral duct making machine. In this essay, we will delve into the world of these complex machines, whose work silently shapes our surroundings.

The layman often overlooks spiral duct making machines, yet their sheer mechanical ingenuity draws fascination from many quarters. Intricate in design, these devices churn out industrial-grade spiraled ductwork, used widely in ventilation and heating systems worldwide. From commercial kitchens to skyscrapers, you’ll find the fruits of a spiral duct making machine‘s labor, pumping air through the veins of our constructed society.

But not all spiral duct making machines are created equal. While they share a common goal – producing high-quality ductwork – their efficiency, reliability, and overall performance vary greatly. An understanding of these key factors is crucial when aiming to acquire a machine of your own – a decision that can significantly influence not only the quality of your products but also the success of your entire operation. Hence, grasping how to choose the best spiral duct making machine becomes a topic of paramount importance, one that we will explore in depth in the following sections.

The Importance of Choosing the Right Spiral Duct Making Machine

In the bustling labyrinth of industrial production, where machines sing their own symphony of efficiency and precision, nothing mars the harmony more than the screech of a poorly chosen tool. Striking the right note begins with choosing an impeccable instrument—the spiral duct making machine. Conceived to sculpt air conduits with surgical precision, the quality of these mechanical behemoths can elevate or plummet the final product’s standard.

Too often, we underestimate the clandestine influence of our choices on the resultant product—an error that manifests conspicuously in inferior workmanship. The making of spiral ducts is far from an exception in this respect. The quality of the machine acts as the unseen hand shaping the duct’s contours, dictating its smoothness, and guiding its stiffness. A top-tier spiral duct machine, humming with precision, can craft ducts akin to the strokes of a master artist—flawless and sturdy. On the contrary, a subpar device would birth ducts akin to a novice’s fumbling sketches—riddled with inconsistencies and woefully inadequate.

Engaging with projects of intricate design and stringent requirements calls for a tool tailored to fit the task. Imagine setting out to construct a colossal manufacturing plant, necessitating miles of air ducts. These aren’t mere tunnels for air, but the plant’s lungs, breathing life into every corner. Specialized machines that meet specific project parameters become essential. Using a machine equipped to handle the task’s scope, complexities, and unique demands ensures that the project stays on track and attains its envisioned quality.

Navigating the maze of machinery options can be daunting. Overlooking critical factors and opting for an ill-fitted spiraling duct machine can lead to an avalanche of repercussions. It’s akin to fitting a square peg in a round hole—the consequences can range from minor setbacks to catastrophic failures. An ill-suited machine may churn out poorly constructed ducts, compromising air quality, and exacerbating operational costs. Worse yet, it could lead to frequent machinery breakdowns, disrupting the workflow rhythm and inflating maintenance expenses.

To borrow an analogy, selecting the wrong spiral duct machine is much like pulling the wrong thread in a complex tapestry—the entire fabric comes undone, with every stitch out of place echoing the initial misstep. It’s vital to grasp this crucial truth: The quality of your output is only as good as the machinery that shapes it. Just as a seasoned musician cherishes their instrument, those invested in creating superior spiral ductwork must value, above all else, the machine that births their creation.

Key Factors to Consider When Choosing a Spiral Duct Making Machine

Embarking on the journey of selecting a spiral duct making machine may trigger a sense of overwhelm at the outset. However, by paying close attention to certain pivotal aspects, such as production capacity and efficiency, one can decisively navigate through the market’s extensive offering. The significance of your machine’s output capacity cannot be overstated. It’s like the engine behind a train, propelling it down the tracks with powerful determinacy. Its horsepower, if you will.

A machine with high production capacity allows creation of ducts at a brisk pace, while maintaining consistent quality. Imagine the analogy of a well-oiled assembly line, where each component fits in seamlessly, enhancing overall productivity. In contrast, a machine unable to keep up with demand is akin to a hitch in this harmonious symphony, leading to unwanted delays and compromised quality. High production capacity combined with stellar efficiency maximizes throughput and minimizes waste, thus ensuring that the machine remains a robust companion in your manufacturing journey.

Diversity of Designs: A World of Choices

Moving forward, it’s crucial to familiarize oneself with the array of spiral duct making machines available. Just as an artist relishes the variety presented by different mediums, manufacturers too experience an analogous thrill when presented with diverse options. From tube formers engineered for high-speed accuracy to those designed for versatility, the choice in the market is vast and varied. This diversity opens the door to enhanced customization and flexibility. Each type presents its own strengths and nuances, and choosing one that resonates with your unique needs is crucial.

The Durability Quotient: A Trusted Ally for the Long Haul

Beyond the immediate considerations of type and efficiency, lies the critical aspect of durability. Much like the foundation of a building, this forms the bedrock of your decision. A machine’s durability is its testament to withstand the rigors of time and usage, its promise of longevity. A hardy machine pays for itself over time, transforming from a mere piece of equipment to a reliable partner in your manufacturing narrative.

Reliability, the close kin of durability, also deserves special mention. A reliable machine functions seamlessly, minimizing downtime and invariably leading to increased productivity. It’s the heartbeat that keeps the operation going, the constant rhythm supporting the melody of manufacturing. Ensuring that your chosen machine embodies these characteristics can prove instrumental in bolstering business productivity and sustainability.

In essence, the criteria of production capacity, diversity in design, and durability form the cornerstone of any well-informed decision related to spiral duct making machines. The key lies in understanding these components individually and appreciating how they intertwine to create a cohesive whole. This intricate dance of factors, when thoroughly grasped, provides the clarity needed to step confidently into the realm of spiral duct machine selection.

Section 4: Sensory Details and Figurative Language in Describing Spiral Duct Making Machines

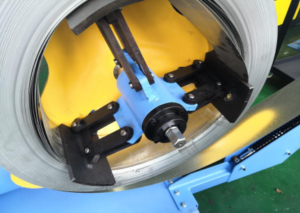

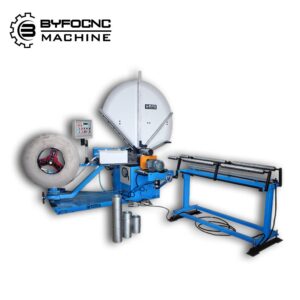

Imagine walking into a bustling factory with the rhythmic hum of machinery vibrating all around you. Your eyes are immediately drawn to an imposing metal contraption standing out like a maestro conducting an industrial orchestra. This is the spiral duct making machine. Its iron form gleams under the harsh fluorescence, while sections bolted together create a beautiful contradiction of raw power and intricate precision. The surface texture, cold and unyieldingly solid beneath hastily running fingertips, is a testament to its unforgiving durability.

Tucked in its heart lies the motor, pulsating rhythmically like a living organism, hidden deep within its steel shell. This powerful heart gives off a steady whir that seems to sing the song of production. Listen closely, and you’ll understand why some equate it to a mason tirelessly chipping away at marble, exposing a work of art with every stroke. Each rotating spiral, each piece of duct molded, is akin to a sculptor revealing his masterpiece from within the stone, one strike at a time.

The operation of a top-tier spiral duct making machine could be metaphorically likened to a ballet dancer. Paradoxical as it may seem, the machine showcases a fluidity that marries strength and grace, similar to a lithe ballerina pirouetting across the stage. Every twist and turn, each whirring movement is deliberate, purposeful, aimed at creating perfect cylindrical spirals. Its movements are so seamless, one might momentarily forget the raw power humming beneath the polished exterior.

Across the vast market of mechanical beasts, what sets apart the truly exceptional spiral duct making machines? It is often their unique characters. Some might sport cooling systems whispering softly while maintaining the optimal temperature, a minor adjustment that extends the machine’s lifespan. Others might possess adjustable cut-off dies, much like a tailor’s nimble fingers adjusting the fabric to stitch the perfect suit. These subtle features may be easy to overlook, but they tip the scales in favor of efficiency and accuracy.

So next time you encounter a spiral duct making machine, allow your senses to guide your understanding. Feel the smooth yet cold surface, listen carefully to the symphony it plays, and observe the ballet of production it performs. Remember, every great machine is not merely an assembly of iron and steel but a testament to human ingenuity – a living entity that breathes life into industrial dreams.

Section 5: Personal Experience and Emotional Connection with Spiral Duct Making Machines

One might wonder, what kind of personal experience or emotional connection can someone possibly have with spiral duct making machines? Let me assure you; the bond runs deeper than you might imagine.

In my years immersed in the world of industrial machinery, I have spent countless hours with these machines, watching them meticulously transform raw materials into perfectly formed spiral ducts. The first time I witnessed this seemingly magical process, a sense of awe washed over me. There it was – a hulking machine humming with energy, effortlessly churning out flawless spiral ducts like a conductor leading a grand symphony. It was a sight that left me both humbled and inspired.

My ensuing years of experience with these machines have endowed me with a unique understanding, akin to the intimate familiarity an artisan might share with their tools. This familiarity has instilled a profound respect for these mechanical marvels and an insatiable curiosity to understand their workings better. Like a seasoned sailor who understands the depth of the ocean, the ebb and flow of its waves, I could predict and interpret the rhythmic hum of the machine, the tune it played speaking volumes about its health and efficiency.

Exploring The Industrial Canvas

With every new project, every new requirement that arose, working with the spiral duct making machines felt like painting on an industrial canvas. Sometimes, it was about crafting ducts of unusual dimensions or dealing with materials that were hard to handle. Each challenge, though daunting at first, eventually stirred a sense of excitement, a reward that awaited discovery. And like an artist lost in their creation, I became engrossed in the process, experimenting, failing, learning, and ultimately succeeding. This cycle, this journey invoked emotions that were as exhilarating as they were educational.

A Symphony of Industry

The spiral duct making machine, to me, is not just another industrial tool. It’s an orchestra playing the symphony of industry, each part precisely coordinated with the others, each movement crucial to the whole. The steadfast rhythm of its operation, the hypnotic dance of its parts, and the humming chorus of its efforts create a lively spectacle, which, oddly enough, brings tranquility to the otherwise chaotic industrial atmosphere.

The Impact Beyond the Known Borders

In the realm of industries where spiral ducts are paramount – HVAC, construction and more, these machines have an impact that cannot be overstated. Ducts created by these stalwart pieces of machinery breathe life into buildings, help keep environments comfortable and safe, and facilitate numerous pivotal processes. Being a part of this chain, contributing to the cycle of industrial utility, invokes a sense of fulfillment that is hard to put into words.

Perhaps this sense of connection, this emotional bond with spiral duct making machines, may seem incomprehensible or even absurd to some. Yet, it is this passion, this ceaseless curiosity and reverence for these mechanical wonders that enables one to truly appreciate their value and strive towards harnessing their full potential. As we move forward to discuss the business aspect of choosing the best spiral duct making machine, keep in mind this underlying emotion that fuels the quest for perfection in the industrial landscape.

The Significance of Choosing the Best Spiral Duct Making Machine for Business Success

Stepping into the realm of business pragmatism, let’s take a closer look at how selecting the best spiral duct making machine can significantly impact the bottom line. It might seem like government bonds or equity shares aren’t the only things that promise a good return on investment. A well-chosen piece of machinery could open avenues for productivity and profitability hitherto unimagined!

The Magic Bullet: Productivity and Efficiency

An artist’s brush strokes are only as bold and precise as the paintbrush they wield, and an industrialist’s productivity is often dependent on the tools they employ. Investing in top-notch spiral duct making machines drives productivity to new heights. It’s akin to replacing a worn-out bullock cart with a high-speed bullet train—speed and efficiency dramatically increase and wastage minimizes. Every minute lost due to inefficiencies or slow production rates is a dent in profit margins, a luxury few can afford in today’s fiercely competitive markets.

Potential Cost Savings and Increased Profitability

The echo of the humming machine doesn’t just churn out spiral ducts—it resonates with the sound of coins clinking into the cash register. Going for a premium model of a spiral duct making machine might seem like a substantial upfront cost, but think of it as planting a money tree. Over time, the initial investment shrinks in comparison to the ongoing cost savings. Like a master chef choosing the finest ingredients, sometimes spending more initially guarantees better results later on. High-quality machines tend to require less maintenance and have fewer breakdowns, curtailing the hidden costs that often sneak up with cheaper alternatives. To parrot an old saying, “penny wise, pound foolish” is not the strategy to adopt here. The increased output also means the potential for amplified profits, making the machine not just a cogwheel in production but a bona fide profit generator!

The Future is Now: Long-Term Benefits for Business Growth and Customer Satisfaction

Choosing the proper spiral duct making machine isn’t just about immediate gains—it’s a long-term, strategic move for business growth. It’s like planting a sapling today and securing shade for the future. When a business has reliable machinery that consistently delivers high-quality products, it solidifies its reputation in the market and builds customer trust. Quality, after all, sells. Compromising on machinery might save a few bucks today, but could cost the goldmine of a loyal customer base tomorrow. Customer satisfaction is the nutrient-rich soil in which businesses thrive, and your choice of machinery can significantly impact the quality of fruits borne.

Concluding this section, it’s clear that the essence of choosing the best spiral duct making machines extends far beyond immediate productivity or financial gains. It affects the very pace and direction of a business’s growth—it’s the wind beneath the wings of success. The right investment today could be the line separating a blossoming enterprise from an industry leader tomorrow.

Section 7: Summary and Restatement of the Importance of Choosing the Best Spiral Duct Making Machine

As we draw the curtains on this technologically-inclined journey, let’s pause to revisit the fundamental insights that have been shared about the choice we make when selecting a spiral duct making machine. This deliberation has never merely been about choosing a piece of machinery; it has always been about committing to quality, operational efficiency, profitability, and long-term growth in business.

The choice of the right spiral duct making machine is akin to setting the foundation stone for a building. As the machine churns out flawless coil after coil, it shapes the framework of our industrial activities, much like how the foundation determines the durability and longevity of a building. We’ve unearthed this truth by diving into the intricacies of the machine’s operation, its design, its potential impact on the production line, and its role in shaping the financial health of a company.

We initiated our discourse with an emphasis on the importance of the right machine selection. The very essence of this decision lies in understanding that the quality of the machine resonates directly with that of the final product. Imagine trying to sculpt a masterpiece with a blunt tool; such a situation mirrors the futility of projects executed using subpar machinery. This correlation between the machine’s standards and the project’s requirements is what accentuates the implications of our choices.

Following this, we delved into key considerations for machine selection: the machine’s functionality, its different types, and their attributes such as production capacity, efficiency, durability, and reliability. Unveiling these aspects, we discovered that beneath the metallic exterior of these machines lie nuanced features offering varying degrees of performance. A discerning eye, hence, is critical to spot the differences and identify the machine fulfilling one’s specific needs.

Our journey then took us through a vivacious description of spiral duct machines, as we painted their portraits using strokes of sensory details and figurative language. The steady hum of a high-quality machine, its robust build echoing reliability, the smell of fresh metal that lingers around it, and the sight of the flawlessly coiled ducts it produces – these are but glimmers of the mesmerizing experience offered by a superior spiral duct machine.

And lastly, we humanized our interaction with these machines by harnessing our personal experiences and emotional connection to them. The profound sense of exhilaration when a machine operates flawlessly, the deep sigh of relief when it meets a project’s demands or the heartfelt admiration for its influence on industries – all these emotions imbue our perspective about these mechanical marvels with deeper resonance and relatability.

To shape it anew, the decision to choose the best spiral duct making machine is more than just an operational necessity; it is an investment in your venture’s future. It is the fuel that powers productivity, efficiency, and profitability. It isn’t merely about ticking boxes in a machine specification list; it’s about aligning the machine’s capabilities with the business’s vision and aspirations.

As we stand at this juncture, let’s absorb the profundity of what this decision encapsulates. Envision the journey of the humble sheet of metal as it enters the machine and emerges as an intricately coiled duct. Now transpose this image onto your decision-making process: with the right choice, your business too can undergo a transformative journey, crafting its success coil by coil, one decision at a time.

Additional Considerations and Resources for Choosing a Spiral Duct Making Machine

In the journey of selecting the best spiral duct making machine, considering the previously discussed core factors is crucial. However, there’s more to it. Some additional considerations, along with resources and manufacturers, can be instrumental in making this important decision.

Extra Tips for Selecting the Perfect Machine

When it comes to complex machinery like spiral duct machines, the devil is often in the details. It’s about looking beyond the conspicuous features to the nitty-gritties that set great machines apart from the mediocre. For instance, consider the machine’s ease of use. Can the personnel operating it adapt seamlessly to its control system? Or will it demand grueling hours of training? How about maintenance—can it be serviced easily or does it require specialized attention?

In the spirit of longevity, scrutinizing the after-sales support provided by the manufacturer is valuable too. Are spare parts readily available? Is there a speedy and efficient customer service response in case of any machine breakdowns? Answering these questions, though seemingly mundane at first glance, can save significant headaches down the line.

Renowned Manufacturers and Suppliers

Selecting the right supplier is as essential as choosing the best spiral duct making machine. Renowned manufacturers like Vicon Machinery, Spiral-Helix, and Mestek Machinery stand out as industry giants vouched for due to their consistent quality and client satisfaction. They don’t merely sell machines; they offer comprehensive solutions, ensuring you don’t walk this path alone. Personal endorsements and online reviews can also give valuable insights into how these companies interact with customers, which is as important as the product itself.

Finding Valuable Resources and Guides

The world around us is brimming with resources that can assist in making an informed decision. For instance, HVAC trade shows and expos could be a treasure cove of information where you can see these machines at work and meet various manufacturers face-to-face. Professional forums and digital platforms like HVAC-Talk or Reddit’s HVAC community can provide hands-on insights and experiences from those working closely with such machinery.

Another invaluable resource is professional consultants specializing in HVAC systems. They can offer personalized advice based on your specific needs and budget constraints. With their insights, they can guide you through the labyrinth of technical specifications to find a machine that truly suits your needs.

In conclusion, while the road to choosing the best spiral duct making machine might seem daunting, it’s far from insurmountable. A careful, detailed analysis—keeping in mind both the primary considerations discussed earlier and these additional factors—can make a monumental difference in your business operations. Coupled with an exploratory approach towards resources and guides available, you can maneuver this decision with wisdom and foresight. Remember, perfection is not just about the big picture; it’s also about appreciating the minute details that often escape the untrained eye.