When it comes to ductwork, two key tools dominate the scene – the spiral duct machine and the spiral duct former. While they might appear similar at a glance, understanding their differences can significantly impact your HVAC system’s efficiency, cost-effectiveness, and longevity. This post will explore these two essential tools in depth, shedding light on their features, functionality, usability, pricing, customer support, and overall reliability. By the end, you’ll have a clear understanding of which tool is the right fit for your unique HVAC needs.

Introduction

Spiral Duct Machine vs Spiral Duct Former: Understanding the Differences

The spiral duct machine and spiral duct former are both integral to the ductwork industry. While they share a similar purpose – that of shaping ducts – their operational methods, functionalities, and features differ significantly. The spiral duct machine is predominantly automated, offering adjustable speed controls, precision, and compatibility with varying duct sizes and materials. On the other hand, the spiral duct former offers manual control, limited speed adjustments, and compatibility with select duct sizes and materials.

The Importance of Spiral Duct Machines and Formers in HVAC Systems

Both spiral duct machines and formers play vital roles in HVAC systems. They’re used to create spiral ducts, which are widely recognized for their superior airflow efficiency, energy conservation, and reduced noise levels compared to traditional rectangular ducts. Whether you opt for a machine or a former depends heavily on your production requirements, budget constraints, and labor availability.

Features and Functionality

Spiral Duct Machine Features and Capabilities

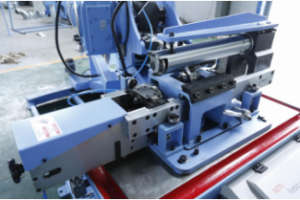

Automated Cutting and Forming Processes

The spiral duct machine stands out for its automated cutting and forming processes. This feature significantly reduces manual labor, enhances precision, and increases production efficiency. With automation, operators can feed in the raw material, set the required parameters, and let the machine do the rest.

Adjustable Speed and Precision Controls

Spiral duct machines come with adjustable speed and precision controls, allowing operators to tweak the machine’s functionality based on the task at hand. This feature offers unrivaled flexibility and allows for optimization of production time and quality.

Compatibility with Different Duct Sizes and Materials

One of the notable advantages of spiral duct machines is their compatibility with different duct sizes and materials. Whether you’re dealing with small residential ductwork or large-scale industrial applications, these machines can handle a broad range of sizes. They can also work with diverse materials like aluminum, stainless steel, or galvanized steel.

Spiral Duct Former Features and Capabilities

Manual Cutting and Forming Processes

Spiral duct formers operate primarily via manual cutting and forming processes. While this implies more hands-on work, it can offer greater control over the duct formation process. Some businesses may prefer this approach for its potential to deliver a more personalized touch to the final product.

Limited Speed and Precision Controls

Unlike their machine counterparts, spiral duct formers offer limited speed and precision controls. While they can still produce high-quality ducts, the production speed and precision are generally less flexible and customizable.

Compatibility with Select Duct Sizes and Materials

When it comes to compatibility, spiral duct formers usually work with select duct sizes and materials. While they may not offer the same breadth of variety as spiral duct machines, they can still cater to a range of HVAC applications with appropriate planning and preparation.

Usability and Efficiency

Ease of Use and Learning Curve for Spiral Duct Machines

In terms of usability, spiral duct machines excel with their intuitive design and automated processes. However, they may have a steeper learning curve initially, especially for operators unaccustomed to automated machinery. With proper training and practice, though, mastering these machines becomes significantly easier.

Efficiency and Productivity of Spiral Duct Machines

Spiral duct machines are designed for efficiency and productivity. Their automated features and adjustable controls allow for rapid production without sacrificing quality. This makes them an ideal choice for operations requiring high volume production.

Limitations and Challenges of Operating Spiral Duct Formers

While spiral duct formers can offer greater control, they also come with their limitations. The manual operation can be labor-intensive, slowing down production speed. They may also require more skilled operators to ensure the precision and quality of the formed ducts. Overcoming these challenges requires careful planning, staffing, and resource allocation.

Pricing and Cost-effectiveness

Spiral Duct Machine Pricing and Value for Money

Initial Investment Cost vs Long-term Savings

The initial investment cost for spiral duct machines is typically higher than that of spiral duct formers. However, the long-term savings in labor costs, increased productivity, and reduced waste can offset this initial expense over time, making it a worthwhile investment for many businesses.

Additional Costs for Maintenance and Repairs

While spiral duct machines can be more cost-effective in the long run, they may incur additional costs for maintenance and repairs due to their complex mechanical systems. Adequate budgeting for these potential expenses is crucial to avoid unexpected financial strain.

Spiral Duct Former Pricing and Value for Money

Lower Initial Investment Cost but Higher Labor Expenses

Spiral duct formers generally have a lower upfront cost which can be attractive to businesses operating on tight budgets. However, they may require more manual labor, leading to higher labor costs over time. Balancing the initial savings against these ongoing expenses is key to determining value for money.

Potential for Increased Material Waste and Inefficiencies

Due to their manual operation, spiral duct formers may potentially lead to increased material waste and inefficiencies compared to automated machines. It’s essential to factor these potential losses into the overall cost-effectiveness analysis.

Customer Support and Training

Availability of Customer Support for Spiral Duct Machines

Technical Assistance and Troubleshooting Services

Most spiral duct machine manufacturers offer robust customer support, including technical assistance and troubleshooting services. This support can be invaluable in resolving issues promptly and ensuring the machine operates at its best.

Online Resources and Training Materials

Many manufacturers also provide online resources and training materials to help operators understand and use their machines effectively. These resources can significantly speed up the learning process and enhance operational efficiency.

Availability ofCustomer Support for Spiral Duct Formers

Limited Technical Assistance and Troubleshooting Services

Compared to spiral duct machines, customer support for spiral duct formers may be more limited. This is because manual formers generally have simpler mechanisms and fewer technical complexities. However, manufacturers still strive to provide assistance when needed.

Lack of Extensive Online Resources and Training Materials

Due to the manual nature of spiral duct formers, manufacturers may not offer as extensive online resources and training materials as they do for their machine counterparts. Operators might need to rely more on hands-on training and experience.

Durability and Reliability

Longevity and Durability of Spiral Duct Machines

Quality of Components and Construction Materials

Spiral duct machines are built with durable components and construction materials. Manufacturers prioritize quality to ensure these machines can withstand the demanding production environments they’re designed for.

Track Record of Reliability and Performance

Spiral duct machines have a proven track record of reliability and performance. They are extensively used in the industry and have undergone rigorous testing to ensure they consistently meet high standards.

Longevity and Durability of Spiral Duct Formers

Quality of Components and Construction Materials

Spiral duct formers also employ sturdy components and construction materials to ensure durability. While they may not have the same level of automation, their reliability is still crucial to achieving consistent results.

Track Record of Reliability and Performance

Reliability is essential for spiral duct formers as well. Their manual operation requires precision and consistency to produce high-quality ducts. Manufacturers strive to deliver reliable formers that can meet industry standards.

Conclusion

Key Differences and Considerations: Spiral Duct Machine vs Spiral Duct Former

Choosing between a spiral duct machine and a spiral duct former depends on various factors, including your production requirements, budget, labor availability, and desired level of automation. The machine offers automated cutting and forming processes, adjustable speed controls, and compatibility with different duct sizes and materials. It excels in efficiency, productivity, and long-term cost-effectiveness. On the other hand, the former allows for greater manual control, customization, and potentially lower initial investment costs. Balancing these considerations is crucial in making the right choice for your HVAC system needs.

Choosing the Right Tool for Your HVAC System Needs

When it comes to choosing between a spiral duct machine and a spiral duct former, it’s essential to carefully evaluate your specific requirements. Consider factors such as production volume, duct size and material variability, available labor, budget constraints, and long-term cost