As industrial facilities continue to expand and modernize, the demand for efficient and reliable HVAC systems has never been higher. One crucial component of these systems is the ductwork, which needs to be produced quickly, accurately, and at scale. Heavy-duty duct making machines are key to meeting these demands, offering unparalleled production capacity and efficiency. In this article, we’ll explore how heavy-duty duct making machines can help increase production capacity in industrial settings.

Introduction

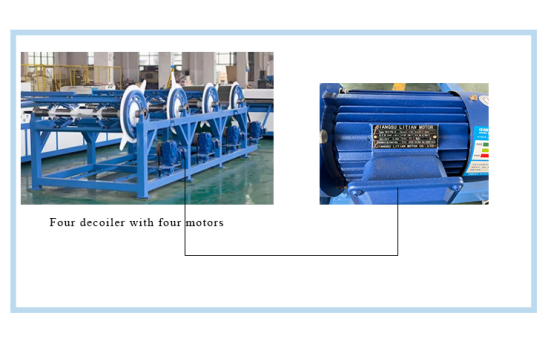

Heavy-duty duct making machines have revolutionized the way industrial facilities produce ductwork. These machines are designed to handle large volumes of metal sheets, cutting and forming them into various shapes and sizes quickly and accurately. They come equipped with advanced features such as automatic feeding systems, computer-controlled operations, and high-speed cutting tools that make the production process more streamlined and efficient.

The Benefits of Heavy-Duty Duct Making Machines

There are several advantages to using heavy-duty duct making machines in industrial settings. First, they significantly increase production capacity, enabling facilities to produce larger quantities of ductwork in less time. Second, they improve accuracy and consistency, reducing errors and minimizing wasted materials. Third, they enhance safety, as workers can operate the machines from a safe distance, reducing the risk of accidents.

Types of Heavy-Duty Duct Making Machines

There are several types of heavy-duty duct making machines available on the market, each designed for specific purposes. Spiral duct machines, for example, are ideal for producing spiral ducts with a smooth inner surface, while plasma cutters can efficiently cut through thick metal sheets. Other popular types include automated duct production lines, duct forming equipment, and duct seaming machines.

How to Choose the Right Heavy-Duty Duct Making Machine

Choosing the right heavy-duty duct making machine requires careful consideration of several factors, including production requirements, budget, and available space. Facilities should also consider the type of ductwork they need to produce and whether the machine can handle the required specifications. Additionally, it’s essential to choose a reputable manufacturer that offers quality products and responsive customer support. To learn more about how to carefully select a duct making machine, please read this article.

Maintenance and Safety

To ensure optimal performance and longevity, heavy-duty duct making machines require regular maintenance and care. Workers should follow all safety guidelines when operating the machines, wear appropriate protective gear, and keep the workspace clean and organized. Routine inspections and repairs can also help prevent breakdowns and minimize downtime.

Conclusion

In conclusion, heavy-duty duct making machines play a crucial role in increasing production capacity in industrial settings. These machines offer unmatched efficiency, accuracy, and safety, allowing facilities to produce high-quality ductwork quickly and reliably. By choosing the right machine, maintaining it properly, and following all safety guidelines, facilities can take advantage of the many benefits heavy-duty duct making machines offer.