Revolutionizing Ductwork Manufacturing with Round Elbow Making Machine Technology

Round elbow making machine technology has revolutionized the way ductwork is manufactured. In this article, we will explore the features and benefits of round elbow making machines and how they have transformed the ductwork manufacturing industry.

What is a Round Elbow Making Machine?

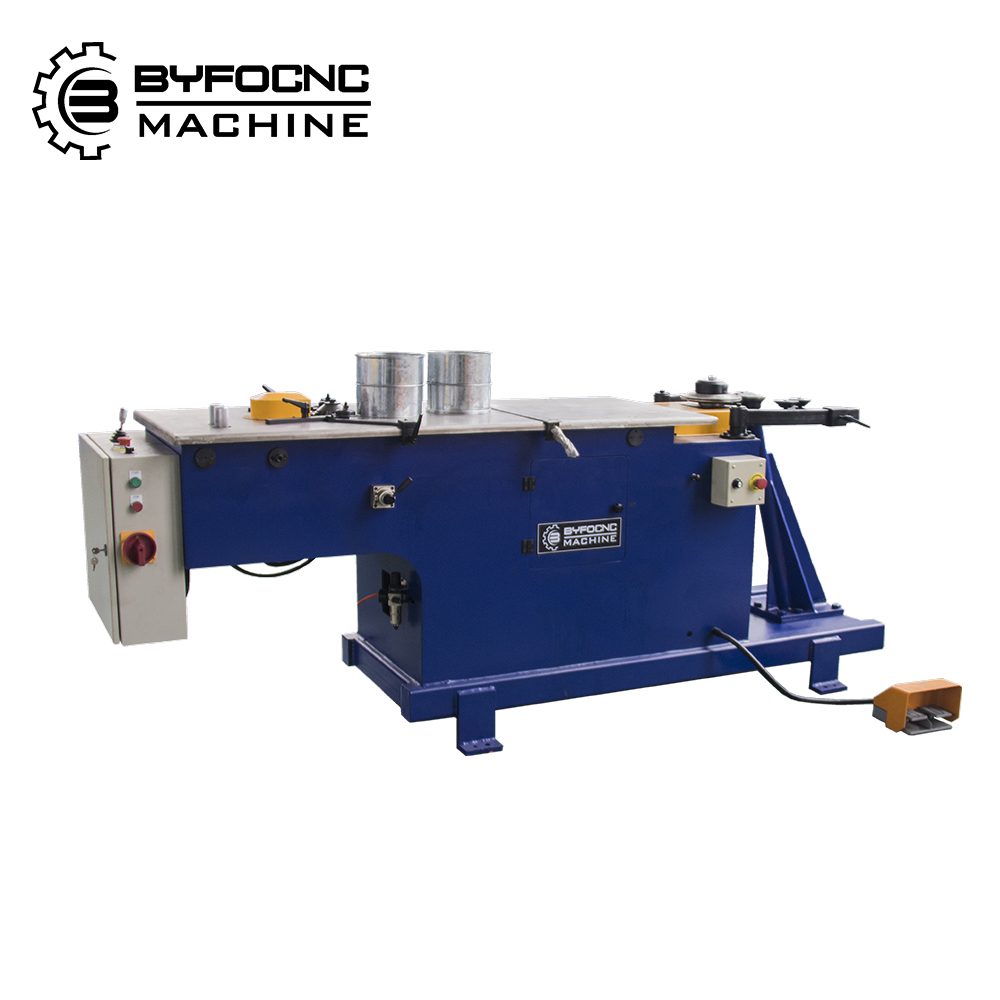

A round elbow making machine is a specialized machine used to manufacture round elbows for HVAC ductwork systems. It is designed to bend and shape sheet metal into round elbows of various sizes and angles, providing high precision and efficiency in ductwork manufacturing.

Features of Round Elbow Making Machines

- 1. Versatility

Round elbow making machines are versatile and can be used in a wide range of applications. They can be used to create round elbows of different sizes and angles, making them ideal for customized ductwork manufacturing.

- 2. High Precision

Round elbow making machines provide high precision and accuracy, ensuring that each round elbow created is uniform and meets the required specifications. This reduces the need for manual adjustments and ensures consistent quality in the finished product.

- 3. Efficiency

Round elbow making machines are efficient and can produce round elbows at a much faster rate than traditional methods. This helps to reduce manufacturing time and costs, improving overall productivity and profitability.

- 4. Customizability

Round elbow making machines offer a high level of customizability, allowing manufacturers to create round elbows with specific angles and sizes to meet their customers’ unique requirements. This flexibility is particularly useful in the HVAC industry, where ductwork must be tailored to fit specific buildings’ heating and cooling needs.

Benefits of Round Elbow Making Machine Technology

- 1. Increased Efficiency

Round elbow making machines have revolutionized the ductwork manufacturing industry by increasing efficiency and cutting down on production time. By automating the process of creating round elbows, manufacturers can produce more ductwork in less time, reducing labor costs and increasing profitability.

- 2. Enhanced Precision

Round elbow making machines offer enhanced precision and accuracy, ensuring that each round elbow is created to the exact specifications required. This reduces the need for manual adjustment and improves the consistency and quality of the finished product.

- 3. Cost-Effective Solution

Round elbow making machines are a cost-effective solution for ductwork manufacturing. By reducing labor costs and increasing productivity, manufacturers can lower their overall manufacturing costs and pass these savings onto their customers

- 4. Customized Solutions

Round elbow making machines offer a high degree of customizability, allowing manufacturers to create round elbows with specific angles and sizes to meet their customers’ unique requirements. This flexibility is particularly useful in the HVAC industry, where ductwork must be customized to fit specific buildings’ heating and cooling needs.

- 5. Improved Safety

Round elbow making machines have improved safety features, reducing the risk of accidents and injuries during the manufacturing process. This protects workers and increases workplace safety, promoting a healthier and more productive work environment.

Progress in manufacturing industry

Moreover, the use of round elbow making machines has allowed for greater flexibility in the manufacturing process. This is particularly useful in the HVAC industry, where ductwork must be customized to fit specific buildings’ heating and cooling needs. By creating custom angles and sizes of round elbows, manufacturers can create ductwork that is more efficient and effective, improving overall energy consumption and reducing costs for building owners.

In addition, the increased efficiency offered by round elbow making machines has had a positive impact on the environment. By reducing production time and labor costs, manufacturers can produce ductwork at a faster rate, decreasing their carbon footprint and promoting sustainability in the manufacturing process.

The safety features of round elbow making machines have also improved significantly over the years. Many modern machines are equipped with safety guards and sensors, reducing the risk of accidents and injuries during the manufacturing process. This protects workers and increases workplace safety, promoting a healthier and more productive work environment.

Furthermore, round elbow making machines have allowed for greater innovation in the design of ductwork systems. By automating the process of creating round elbows, manufacturers can experiment with different angles and sizes, creating new and innovative ways to distribute air throughout buildings.

Conclusion

In conclusion, round elbow making machine technology has transformed the ductwork manufacturing industry. With its high precision, efficiency, customizability, cost-effectiveness, and safety features, it offers numerous benefits to manufacturers, distributors, and customers alike. As the demand for customized and efficient ductwork continues to grow, round elbow making machines will continue to play an essential role in the HVAC industry.